Rapid Lead times

Production Volumes and Quality Control

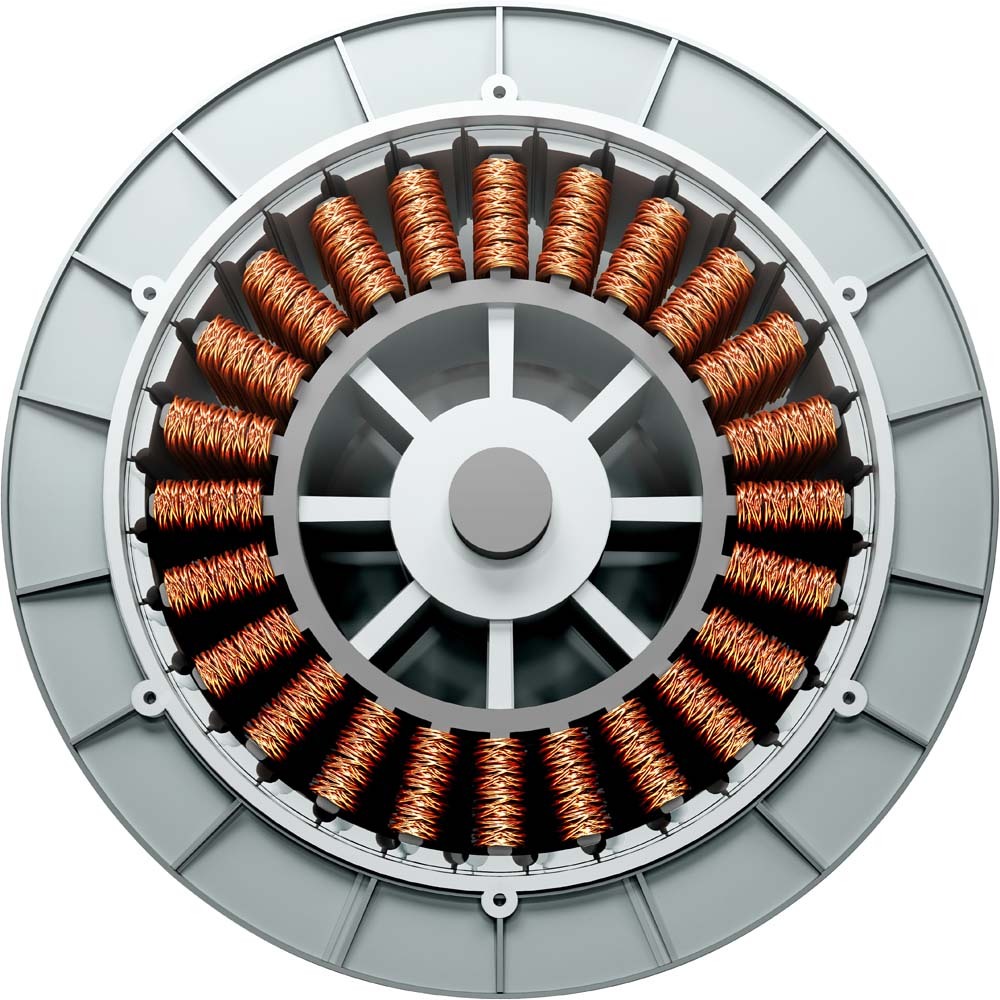

In addition to motor and cable assembly design and support, we deliver turnkey prototypes in low volumes (1 to 25 units) to support proof-of-concept and low rate initial production (LRIP) efforts. Our turnaround is as low as one week — and we will handle the packaging and logistics. We can also deliver assemblies of 25 to 500 units in as little as three weeks.

Working through Trust Automation, we can now support larger-scale volumes and logistics with ISO9000 and AS9100 certified quality. Use the form below to request more information, or contact us at

info@nortronicsmotors.com, +1-918-794-6022.